We form

The Future

Combined Strength. Unsurpassed Innovation.

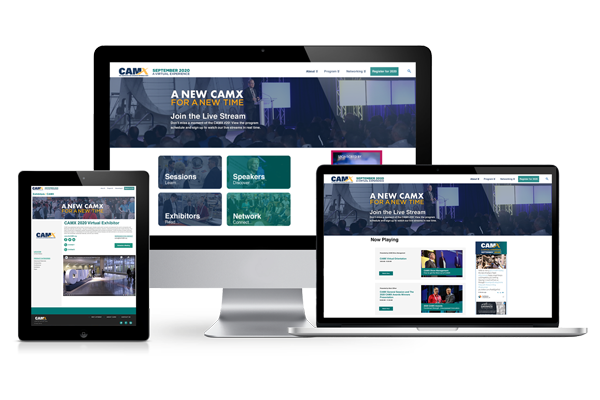

CAMX – the Composites and Advanced Materials Expo – is the largest, most comprehensive composites and advanced materials event in North America.

Conference Sept 9-12, 2024

Exhibition Sept 10-12

San Diego Convention Center, 111 W Harbor Drive

San Diego, CA 32101 USA

Latest at CAMX

CAMX 2024 Awards APPLICATION OPEN

The Poster Session is accepting applications until June 1st. CAMX Award and ACE programs are accepting applications until June 21st.

CAMX 2023 WRAPS UP

CAMX 2023 was one for the books, with a record-breaking 525 exhibitors and our largest-ever exhibit hall spanning over 130,000 square feet. See the innovation for yourself at CAMX 2024 in San Diego, CA!

Sign Up for CAMX Connection

CAMX releases monthly eNewsletters, providing readers with articles on composites and advanced materials, viewpoints from speakers, and upcoming deadlines, as well as updates on programming, the exhibit hall.